Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

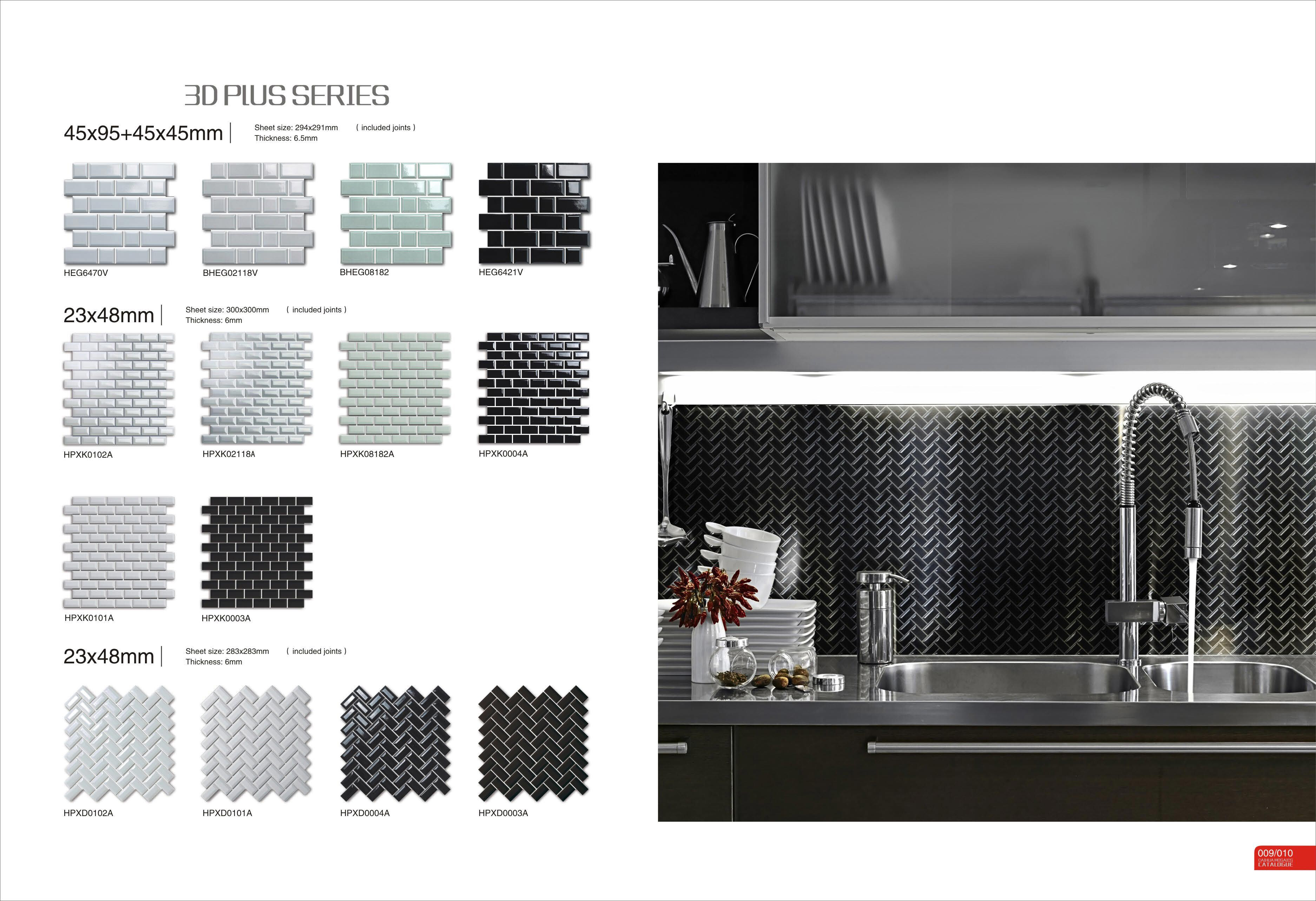

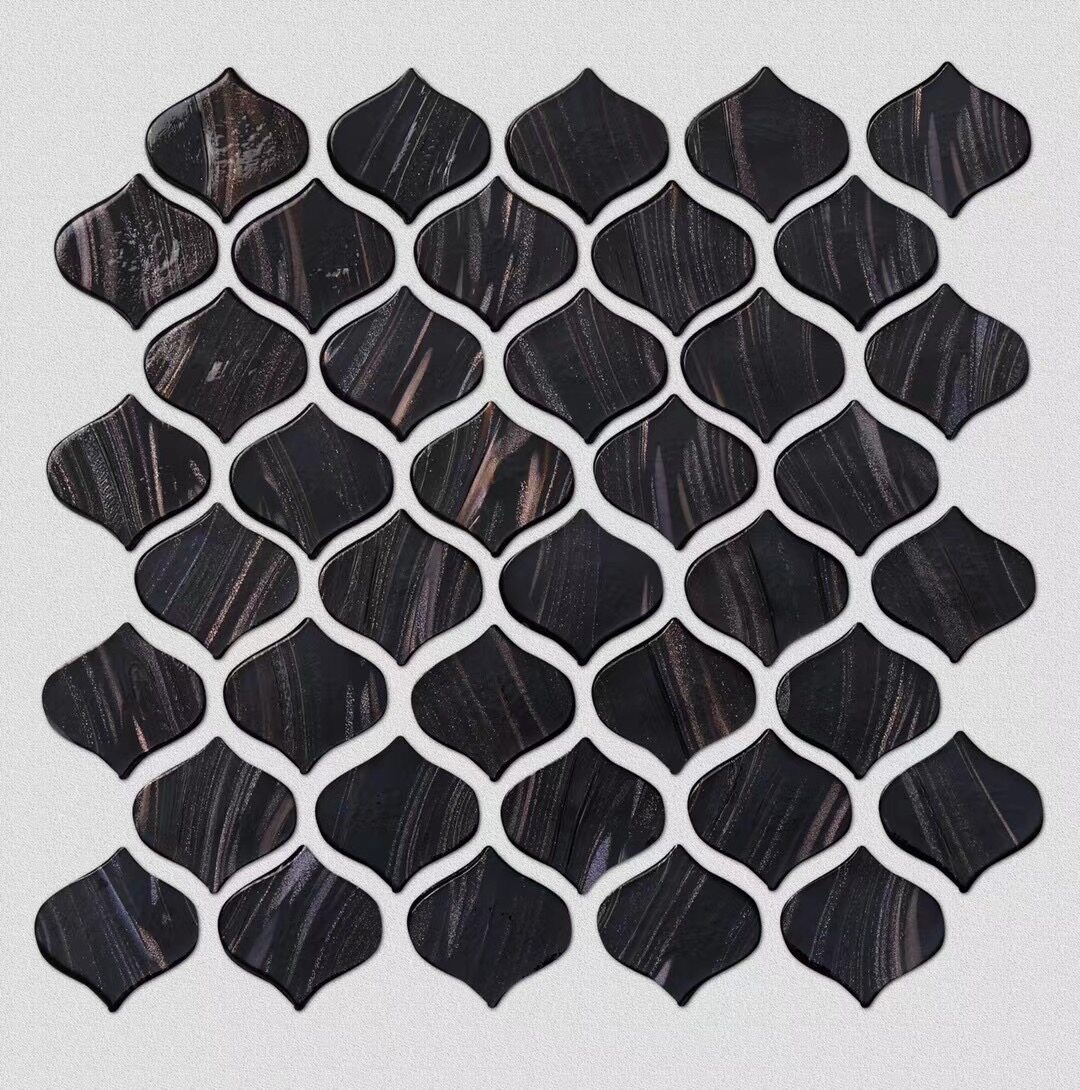

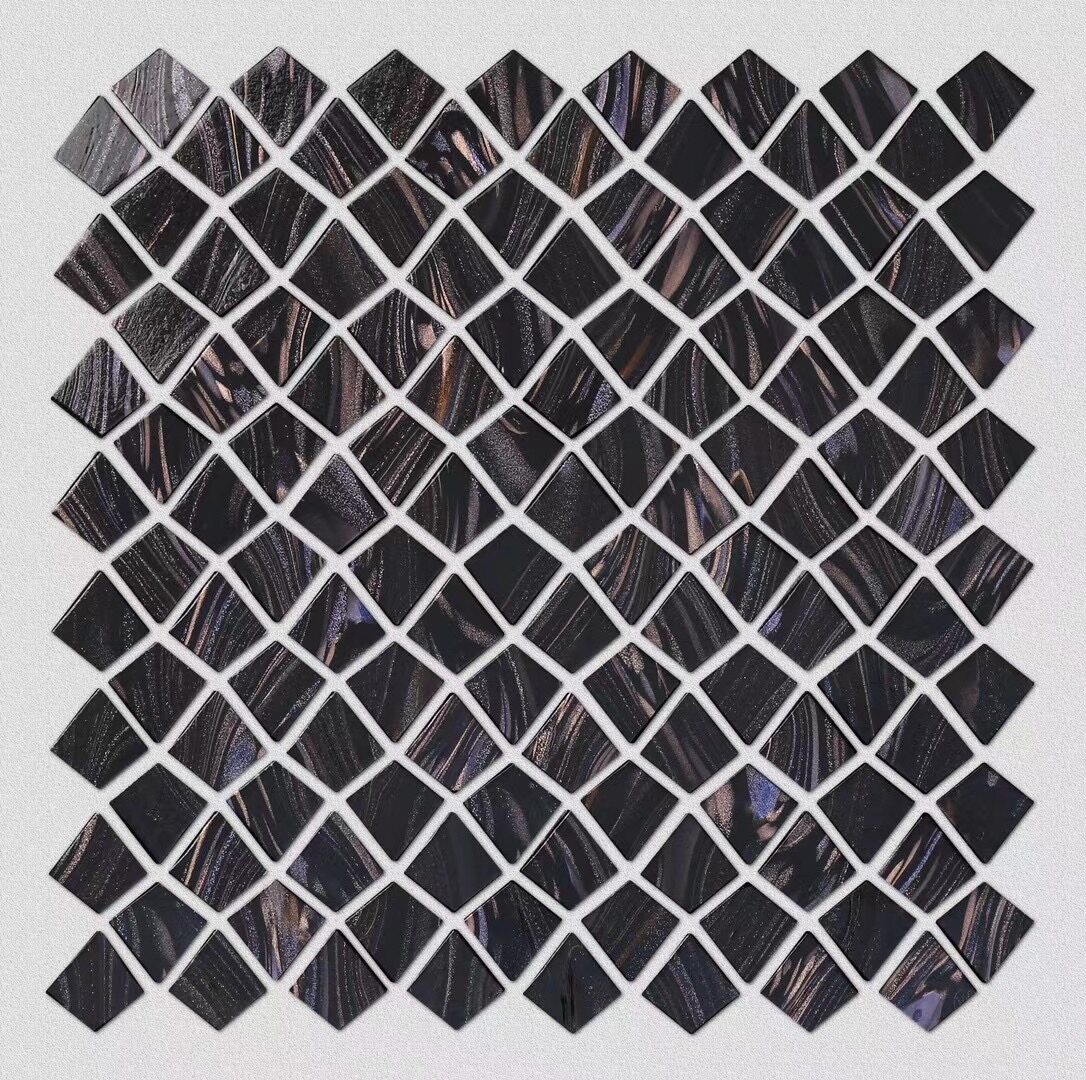

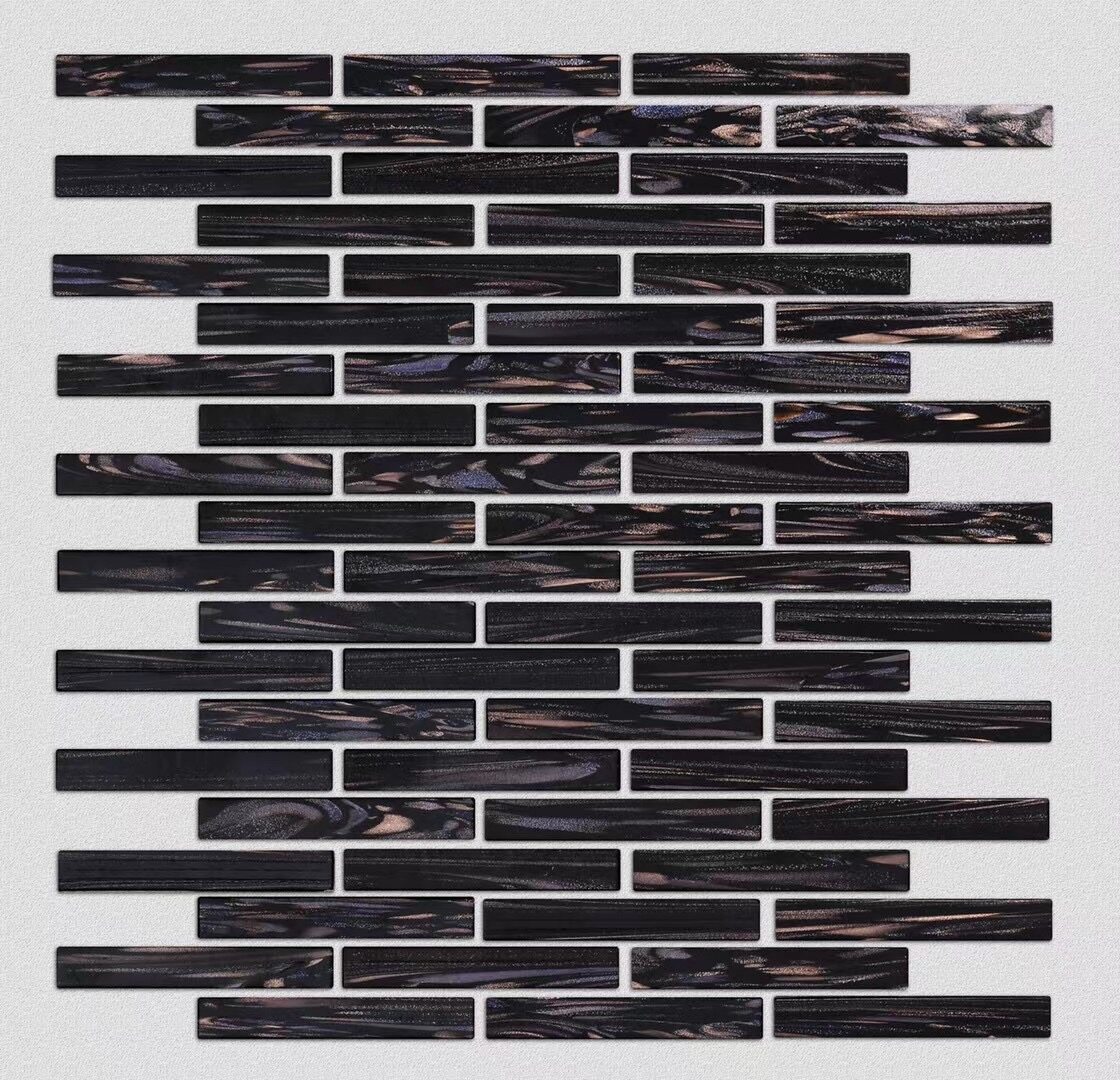

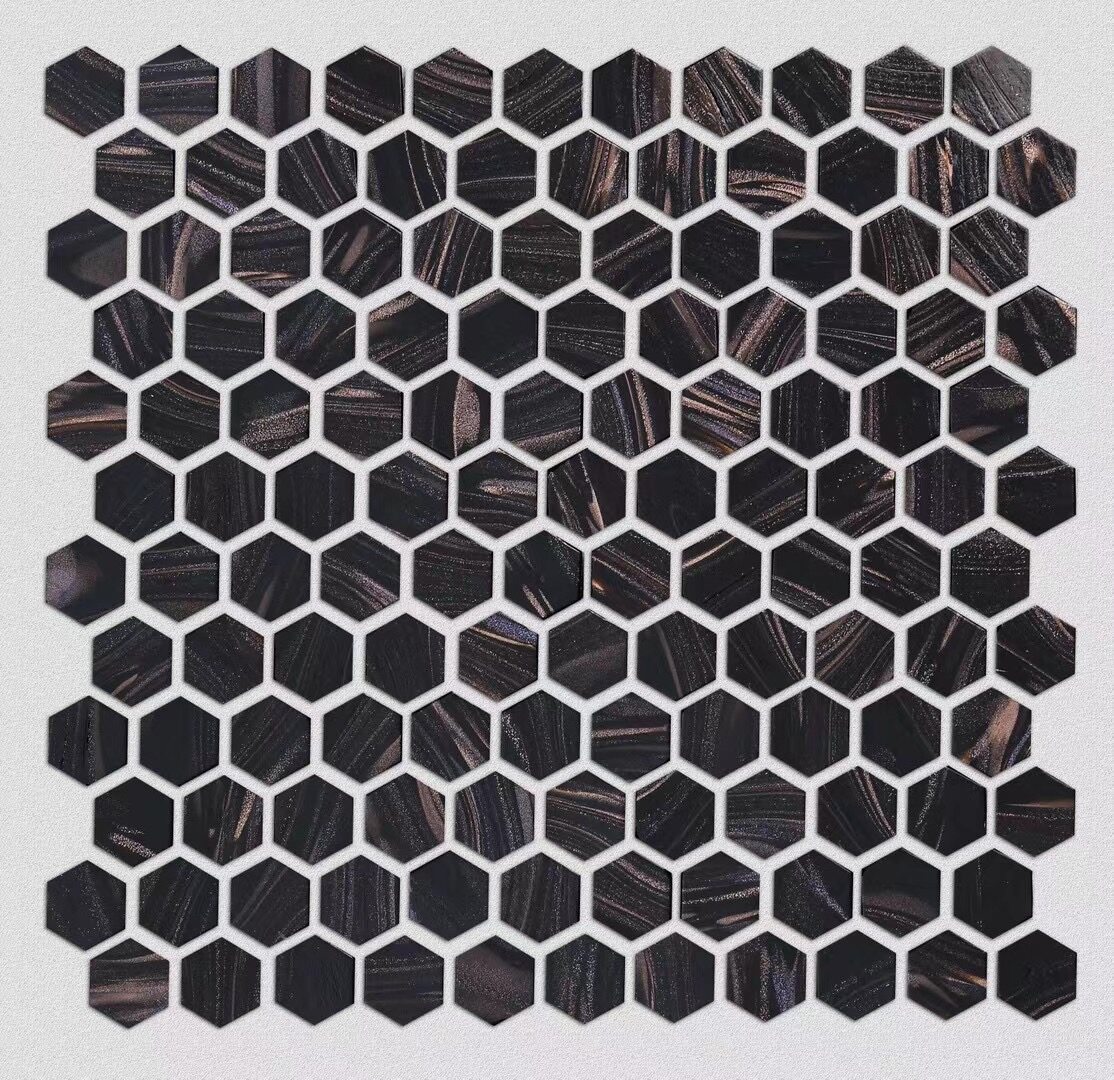

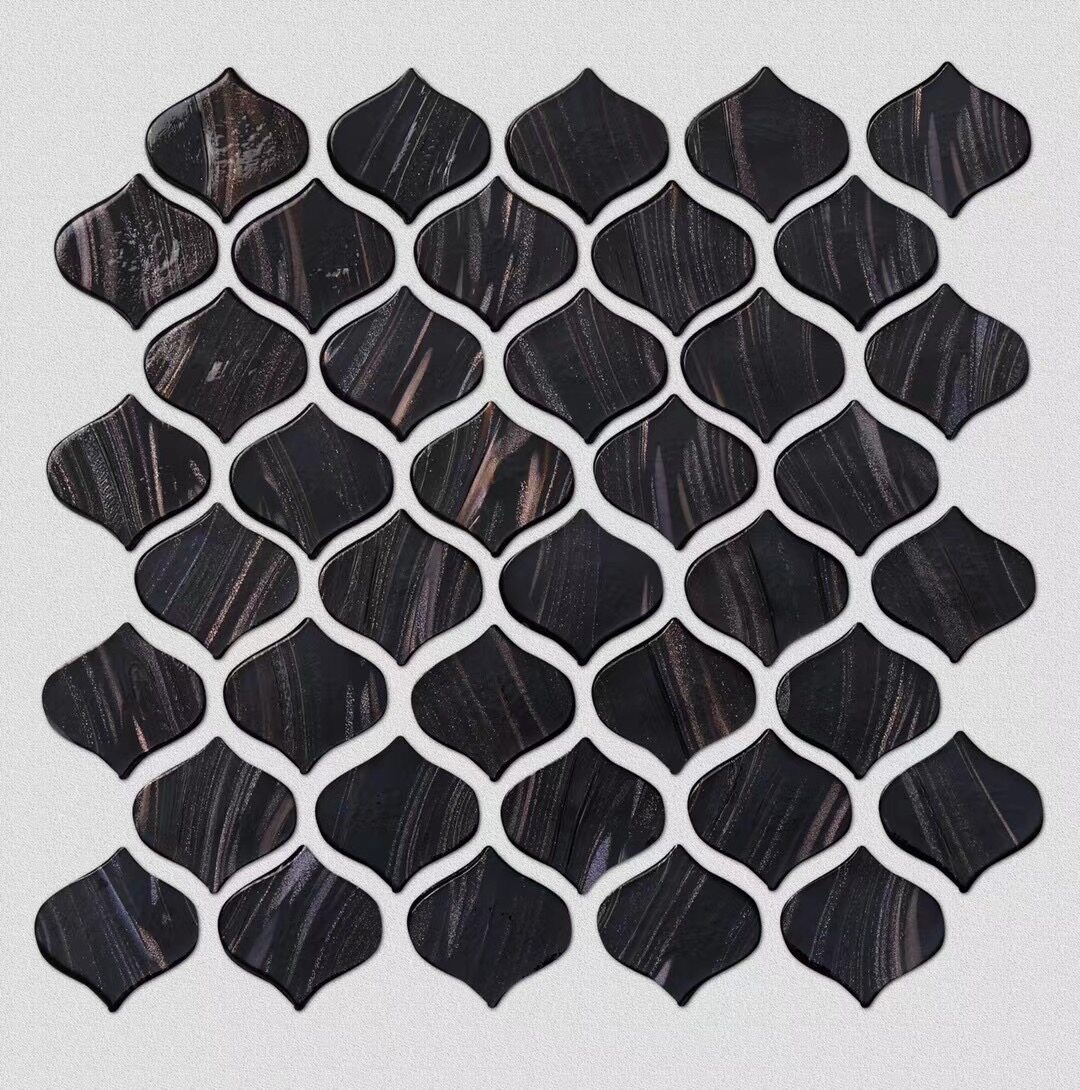

Marble mosaic tile is a tile with unique beauty. Its beauty is due to its shiny surface, which highlights the design and pattern of the tile well. We should say that the colors and models of this tile are very different.

In addition, this tile is compatible with different decoration styles too. That way, you will not be limited in enjoying its beauty. The patterns and geometric shapes of these tiles match well with the frames of many decoration styles.

If it is a brick wall surface, the wall surface shall be cleaned before plastering, and the parts that are easy to be damaged and loosened such as the window sill, window sleeve, and waistline shall be inspected and treated. Finally, the wall surface shall be wetted with water. If it is a concrete wall, the loose concrete, mortar and other sundries on the wall shall be removed first, and the convex part shall be chiseled flat. If it is a smooth wall, roughen it with a roughing machine first. The release agent attached to the wall can be brushed clean with a 10% strength alkali solution. After the wall is watered and wetted, 2-3mm thick putty mortar shall be scraped with cement mortar, or fine cement mortar shall be thrown to increase its adhesion.

If it is a brick wall, after the wall is wet, the cement mortar shall be used as the leveling layer in layers. The mortar thickness is generally 12-15mm, and the screening shall be carried out. In the case of an aerated concrete wall, before plastering the bottom mortar, the wall surface shall be watered and brushed with an interface treatment agent, which shall be plastered at the same time. If it is a concrete wall, the wall surface shall be watered and brushed with an interface treatment agent, and the cement mortar leveling layer shall be plastered in layers, with a thickness of 10-12mm. When the thickness of the flat screeded surface exceeds 12mm, the nail grid reinforcement measures shall be taken for layered plastering, and the surface shall be roughened and watered for curing.

Bricks shall be selected and arranged before snapping the line. The division must be comprehensively arranged at the door and window openings, windowsills, cornices, waistlines and other positions according to the construction drawings and horizontal and vertical decorative lines. When arranging bricks, special attention shall be paid to the structural dimensions of wall corners, wall stacks, awning surfaces, window sills, and other details, and the dividing lines shall be arranged according to the whole mosaic. Only the horizontal joint of the division shall be flush with the window sill and the door and window face, and the vertical division line shall be arranged in a whole line on the balcony and the window side. Snapping shall be carried out after the leveling layer is completed and the inspection is qualified. First, the vertical line of the external corner of the wall and the horizontal line of the upper opening of the inlay (two baselines) shall be snapped according to the detailed layout of the bricks; Then pop up a horizontal dividing line according to each mosaic; Finally, press the mosaic of each or 2-3 lines to pop up the vertical dividing line.

When pasting mosaic, it is generally carried out from top to bottom. Before plastering the bonding layer, brush a layer of plain cement slurry on the wet leveling layer, and plaster a 3mm thick paper reinforced lime paste cement mixed mortar bonding layer. When the bonding layer is pressed by hand without pit marks, snap lines on it to divide it. At this time, the mortar is still soft. At the same time, lay each mosaic on the wooden board (with the bottom facing up), wipe the adhesive surface of the mosaic with wet cotton yarn, and then brush it with a small brush dipped in water. Then, scrape a layer of 2mm thick cement slurry on the mosaic pasting surface, press it down with an iron trowel while scraping, and gently tap the wood plate to vibrate, so that the cement slurry is filled in the joint and bubbles are discharged. Finally, brush water and wet the adhesive layer, paste the mosaic on the wall according to the line and guiding rule, and gently tap and press with a wooden hammer to make the paste more firm.

The hard pasting method is to sprinkle water on the leveled layer with the snapped line, scrape a layer of plain cement slurry with a thickness of 1-2mm, and then operate according to the soft pasting method. The disadvantage of this method is that the dividing line snapped by the leveling layer will be covered by a plain cement paste, which can be followed wirelessly when paving mosaic.

Sprinkle fine sand cement dry ash on the back of the mosaic to fill the joint, then scrape the ash with an ash knife, sprinkle water to wet the dry ash in the joint into cement mortar, and then paste the mosaic on the wall according to the soft paste method. It should be noted that the dry mortar in the joint cell should be filled, and the watering should be appropriate. If it is too dry, some dry ash in the joint will leak out when the paper is removed, resulting in no ash in the joint. If it is too wet, the mosaic cannot be lifted and cannot be mounted. When the mosaic is pasted by this method since the seam is well filled, the link of wiping the seam can be omitted, and only a little wiping is required after the paper is removed.

The mosaic shall be aligned according to the seam, and the distance between joints shall be the same as that of each row of joints. Place the hardwood on the pasted mosaic paper, knock the hardwood with a small wooden hammer, and knock it one by one to ensure the smoothness of the veneer. After the adhesive layer starts to solidify, you can get the mosaic face paper with a soft bristle brush, and the paper can be removed after the face paper is soaked. Before uncovering the paper, try to uncoil it first. Sprinkle cement ash into the wet paper water and mix it evenly, which can speed up the water absorption speed of the paper surface and advance the paper uncovering time. When lifting the paper, it should be lifted down in order, and it is forbidden to lift it out.

After the paper is removed, if some small particles are found to fall, they should be replaced immediately. If a "jumping block" or "blind seam" is found, it shall be pulled out and reset with a steel knife in time to make the seam horizontal and vertical. After the joint is filled, a wooden clapboard shall be padded to compact the brick surface once to enhance its adhesion. This work must be completed before the initial setting of cement.

The joint shall be wiped with a rubber scraper first, and the plain cement paste of the same variety, color, and consistency as that of the mosaic shall be fully scraped on the mosaic, and the cotton yarn can be dipped in the paste for patching at some parts. After wiping, the plain paste will seriously pollute the mosaic surface and must be cleaned in time. The wall cleaning shall be carried out after the mosaic adhesive layer and the pointing mortar are set.